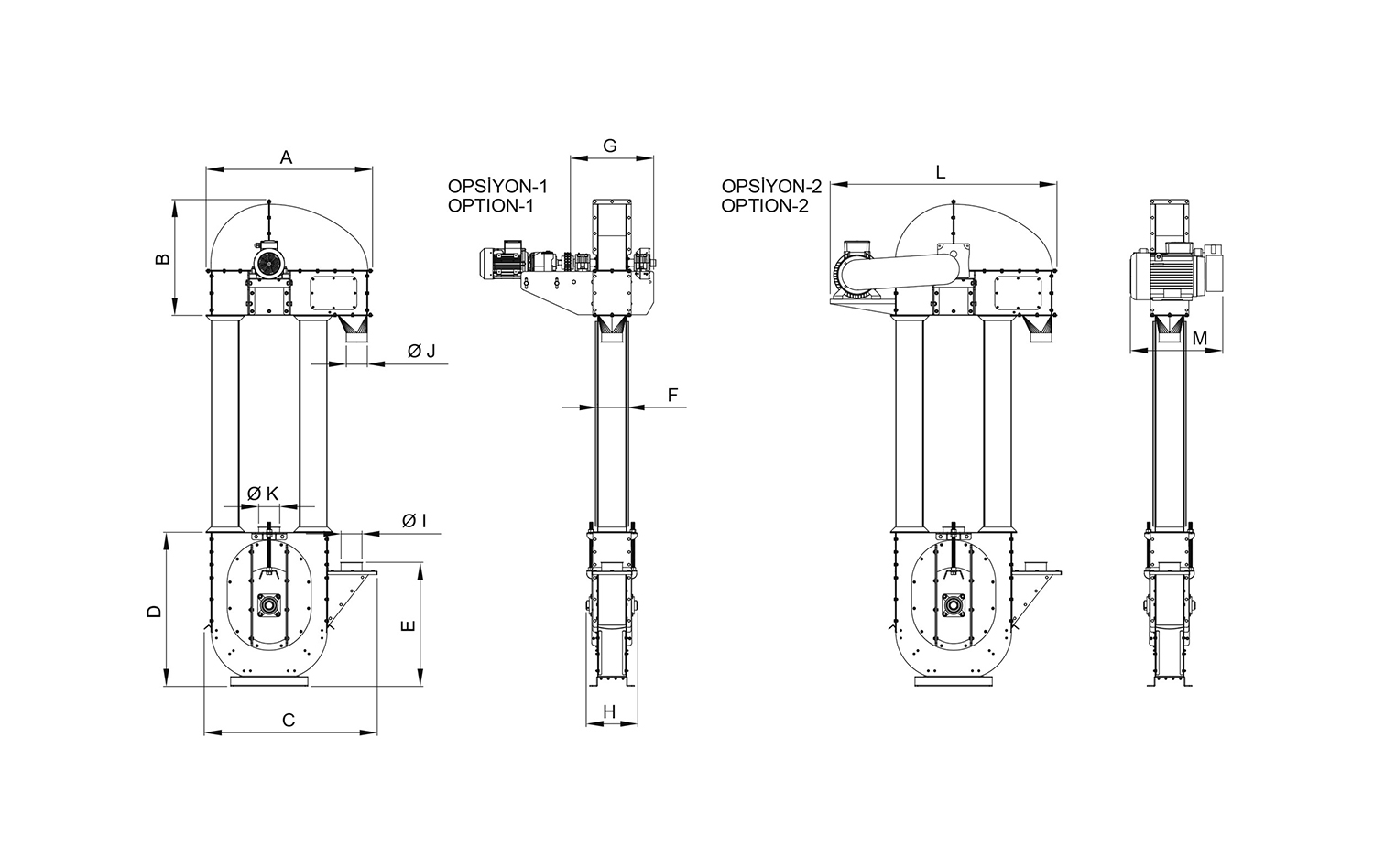

TECHNICAL TABLE

| Model Type | A | B | C | D | E | F | G | H | I | J | K | L | M | Pulley (Ø) | Belt (mm) | Bucket (mm) | Capacity Wheat (t/h) | Flour (t/h) | Bran (t/h) | Weight (kg) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| OEL 150x160 | 950 | 660 | 990 | 880 | 710 | 160 | 470 | 300 | 120 | 120 | 120 | -- | -- | 385 | 120 | 100 | 9 | 6 | 3 | 200 |

| OEL 180x180 | 985 | 660 | 1020 | 880 | 710 | 180 | 500 | 320 | 120 | 120 | 120 | -- | -- | 385 | 140 | 120 | 14 | 10 | 5 | 210 |

| OEL 200x200 | 1025 | 700 | 1065 | 880 | 710 | 200 | 520 | 340 | 150 | 150 | 150 | -- | -- | 385 | 160 | 140 | 22 | 15 | 8 | 220 |

| OEL 220x220 | 1165 | 725 | 1100 | 880 | 710 | 220 | 535 | 360 | 150 | 150 | 150 | -- | -- | 385 | 180 | 160 | 29 | 20 | 11 | 245 |

| OEL 250x250 | 1220 | 755 | 1160 | 880 | 710 | 250 | 570 | 400 | 150 | 150 | 150 | -- | -- | 385 | 200 | 180 | 38 | 26 | 14 | 260 |

| OEL 300x300 | 1420 | 830 | 1365 | 980 | 810 | 300 | 620 | 450 | 200 | 200 | 150 | 210 | 800 | 425 | 260 | 240 | 100 | 65 | 35 | 300 |

| OEL 350x350 | 1650 | 1010 | 1390 | 1010 | 1000 | 350 | 760 | 460 | 200 | 200 | 200 | 210 | 800 | 425 | 300 | 280 | 120 | 85 | 38 | 370 |

| OEL 400x400 | 1650 | 1010 | 1390 | 1010 | 1000 | 400 | 950 | 500 | 200 | 250 | 200 | 210 | 900 | 425 | 360 | 340 | 145 | 107 | 48 | 400 |

As Milma Milling Machines, we have compiled the most frequently asked questions in order to clarify all the details that our valued customers may need.

What raw materials can Millma milling machines be used to process?

As Millma, we manufacture milling machines that can be used in a wide range of applications, from flour production to feed mills, from spice grinding to the crushing of mineral-based products. Our systems enable the efficient processing of grains such as wheat, barley, corn, as well as different granulated and micronized products such as lentils, chickpeas, black pepper, rock salt and calcite.

How is energy efficiency achieved in Millma machines?

Energy saving is one of the fundamental criteria that Millma prioritizes in the design and engineering process. Thanks to the special motor technologies, intelligent frequency control systems and optimized rotor-transition designs we use, low energy consumption is achieved without compromising production capacity. In this way, you minimize your operating costs and support environmental sustainability.

What support does Millma offer during the installation and commissioning of the machines?

Millma does not leave its customers alone in after-sales technical support processes. All our machines are installed on-site with our expert engineers and put into operation with operator training. In addition, your operational continuity is secured with spare parts supply, maintenance protocols and remote support services.

What is the main difference between Millma milling machines and competing products?

Millma stands out from its competitors by combining high strength, long life and processing precision in a single structure. Each product is designed with unique engineering solutions developed by our R&D unit. Our domestic and international reference projects are concrete indicators of our understanding of quality and the importance we attach to customer satisfaction.

Contact Us Now

You can get detailed information about our products by contacting us.

+90 (332) 249 42 00

info@millma.com.tr

Büyük Kayacık OSB Mahallesi 405 Nolu Sokak No:12/1 Konya/TÜRKİYE